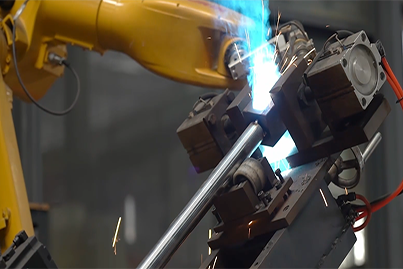

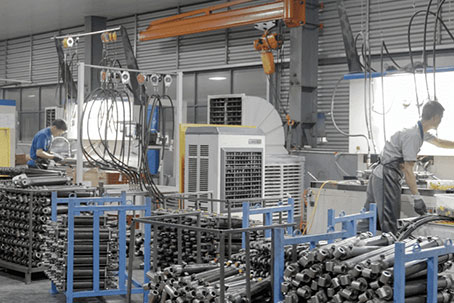

Our factory covers an area of 13,000 square meters with modern-standard workshops and cutting-edge equipment. The 6S and ERP management systems are rigidly implemented throughout our whole company. Our factory is an ISO9001 and CE certified manufacturer.

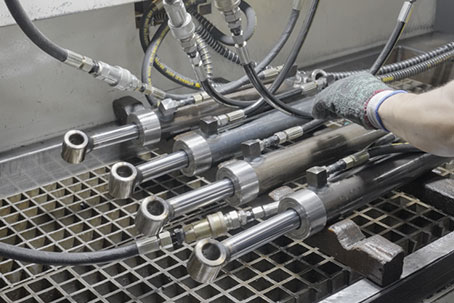

As a family-owned business effortlessly operated by two diligent generations, we value our business and our hydraulics like our children. We are serious about our hydraulic system, and we take customers’ needs seriously. We are willing to grow with all partners, and to support partners in every possible way we can to survive it together