PROJECT INFO

- Project Name: Hydraulic Solution for Dumping Platform

- Client Industry: Seafood Transportation

- Requirement: Lifting capacity of 30 tons, safe, rapid lifting and lowering

- Delivery Time: December 13, 2025

- Order Code: ASPI25111201

- Model: YZBL200-C11-14

- Operation Pressure: 10 MPa

- Pump Flow: 48 L/min

- Motor Power: 11 kW

- Tank Capacity: 200 L

PROJECT BACKGROUND

Facing unique challenges in seafood logistics, our client needed a high-performance hydraulic system for a new unloading platform. The solution had to guarantee exceptional lifting power, rapid response, and reliable long-term operation in a high-moisture, corrosive environment, all while protecting valuable product quality.

SPECIFIC REQUIREMENTS

Safety: The hydraulic station must provide reliable pressure holding capability, ensuring goods and personnel remain protected during all unloading operations.

High Speed: Quick up-and-down platform movement to minimize handling time and safeguard seafood quality.

Project Solution

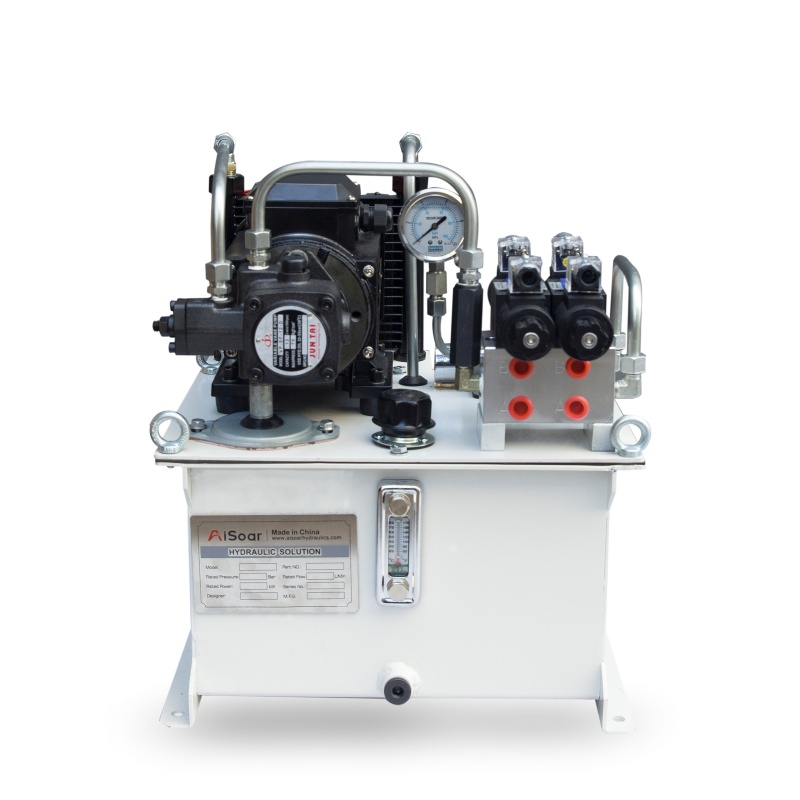

Our Custom Hydraulic Power Unit

To address the client’s requirements, our engineers delivered a purpose-built hydraulic power pack, integrating innovative features to maximize safety, speed, and reliability:

Technical Highlights

- Precision-Engineered Circuit Design

Leveraging advanced hydraulic simulation and calculation tools, our design team developed a dedicated circuit schematic tailored to the 30-ton application. This ensures optimal flow management, minimal energy loss, and balanced pressure distribution throughout the lifting cycle.

- High-Efficiency, Industrial-Grade Components

The system utilizes an 11kW premium hydraulic motor paired with a 48 L/min high-flow pump. This configuration not only delivers rapid lifting and lowering but also improves energy efficiency—minimizing operating costs under heavy-duty, continuous-use scenarios.

- Integrated Electronic Controls for Smart Operation

Safety and convenience are further enhanced by a robust electrical control cabinet and an ergonomic wired remote pendant. This enables precise operator control with one-touch emergency stop, automatic limit detection, and performance monitoring—greatly reducing risks and downtime.

- Corrosion-Resistant Construction

All wetted hydraulic parts feature anti-corrosive coatings and seals, specifically chosen for harsh marine and seafood industry environments. The 200L steel tank is internally treated for moisture resistance, extending the life of the system.

- Comprehensive Safety Redundancies

The circuit incorporates dual fail-safe pressure-holding valves and overload protection. Every lift cycle is monitored to ensure hydraulic integrity and product safety.

PROJECT RESULT

The custom hydraulic power unit was delivered on schedule. Upon commissioning, it demonstrated rapid and stable lifting and lowering performance, fully meeting our client’s requirements for efficiency and operational safety. The client expressed high satisfaction with the system’s reliability and speed, and the installation has since contributed to improved seafood handling efficiency and product quality.