Project Info

- Project Name: SMC10 Barge Combined Jackup System

- Client Industry: Offshore platforms, ocean engineering

- Requirement:Control the jackup system of the barge platform,provide power for the crane.

- Delivery time:2025.10

- Order Code:

- Model:DHPU130/4-97

- Operation Pressure: 300 bar

- Pump Flow:130 L/min

- Motor Power:130 HP

- Tank Capacity:500 L

Project Background

Our client currently requires a hydraulic system for use on an offshore floating platform, hence demanding high standards of corrosion resistance and reliability. Furthermore, the hydraulic power unit (HPU) must possess transportability and mobility, whilst retaining operational capability during power outages. This HPU must meet high-flow, high-pressure requirements to serve as a power source for various equipment on the platform.

On 9 July, 2025, we formally commenced the project design for our client.

Customer Specific Requirements

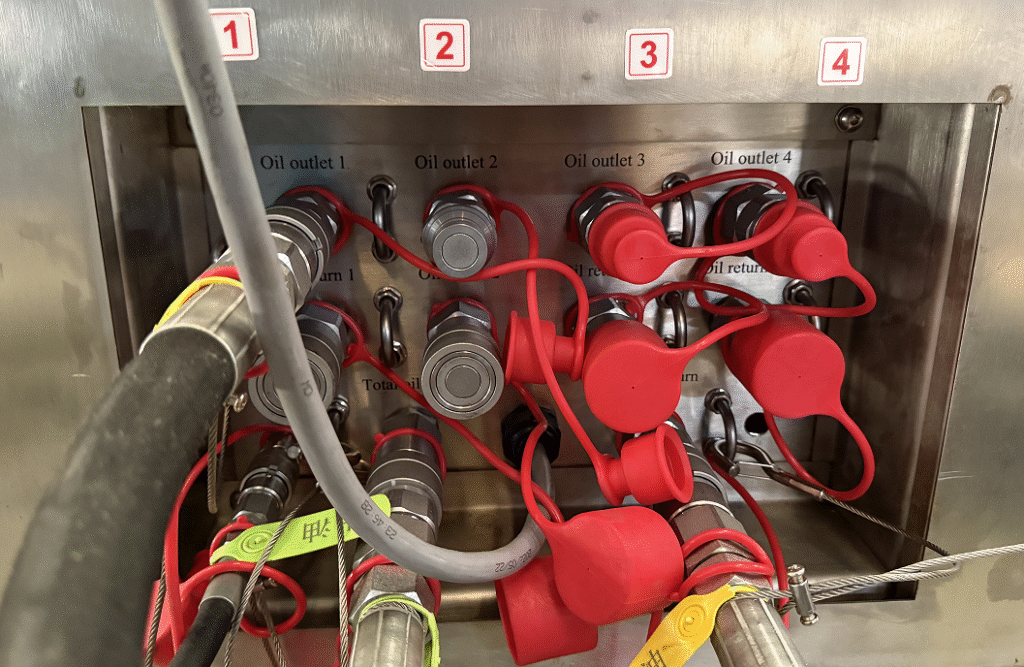

1)Plug and Play

2)Simultaneously providing power sources for different devices

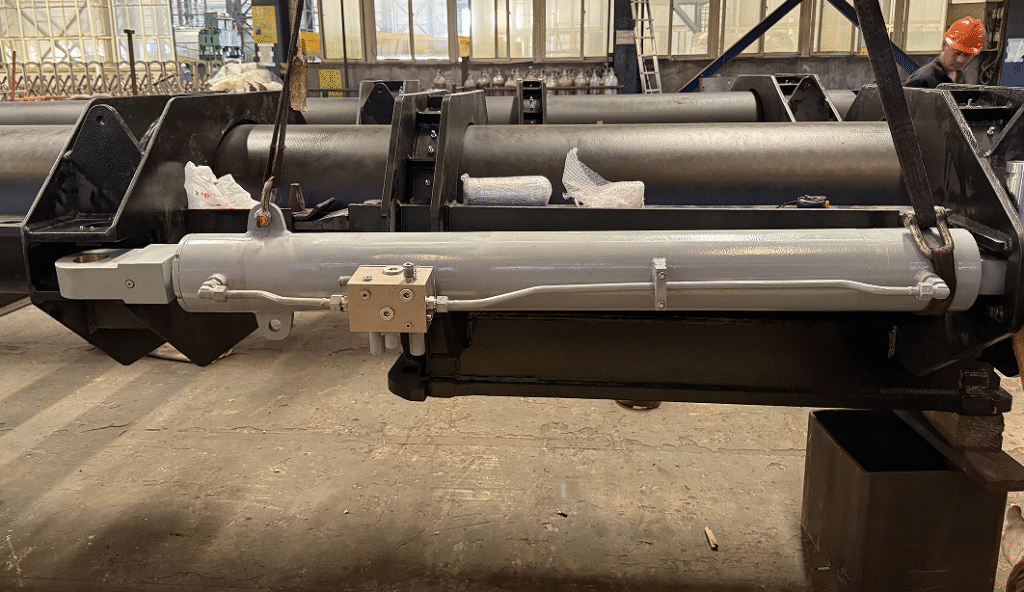

3)Two oil cylinders on the same leg need to be synchronized.

Project Solution——Barge Combined Jackup System

1. Adopting diesel power station,diesel driven, no additional electrical equipment required.

2. HPU adopts a steel pry frame structure with good anti vibration performance and stable and reliable load operation.

3. The main components are imported brands, and the fittings are made of stainless steel material.

4. Equipped with Danfoss series dual variable piston pump. Simultaneously equipped with Danfoss manual proportional multi way directional valve,form a load sensitive circuit.The power loss of the system is relatively low. Uniform distribution of hydraulic system flow.High efficiency and fast response.

5. The hydraulic cylinder adopts a special coating,Has good corrosion resistance performance.The oil cylinder is integrated with a safety valve group,At the same time as protecting the oil cylinder, it also activates the support function for the support legs.

6.Each set of leg cylinders is equipped with a hydraulic synchronous motor to improve synchronization performance.

Project Result

29 August 2025, Completion of production for the entire project

The client conducted a final on-site inspection of the project and expressed great satisfaction with the outcome.