Is your hydraulic cylinder underperforming, leaking, or causing costly downtime? Incorrect seal selection leads to wasted resources, significant damage, and operational halts. Finding the right seals is critical for restoring and optimizing performance.

To find the right seal for your hydraulic cylinder, you must accurately identify the cylinder model, measure key dimensions, understand operating conditions (pressure, temperature, fluid type), and match these with appropriate seal types and materials. A quality seal kit is essential for efficient system operation and extended lifespan.

By delving into these crucial elements, you can easily match your hydraulic cylinder with a tailor-made sealing solution, ensuring durable and efficient equipment operation.

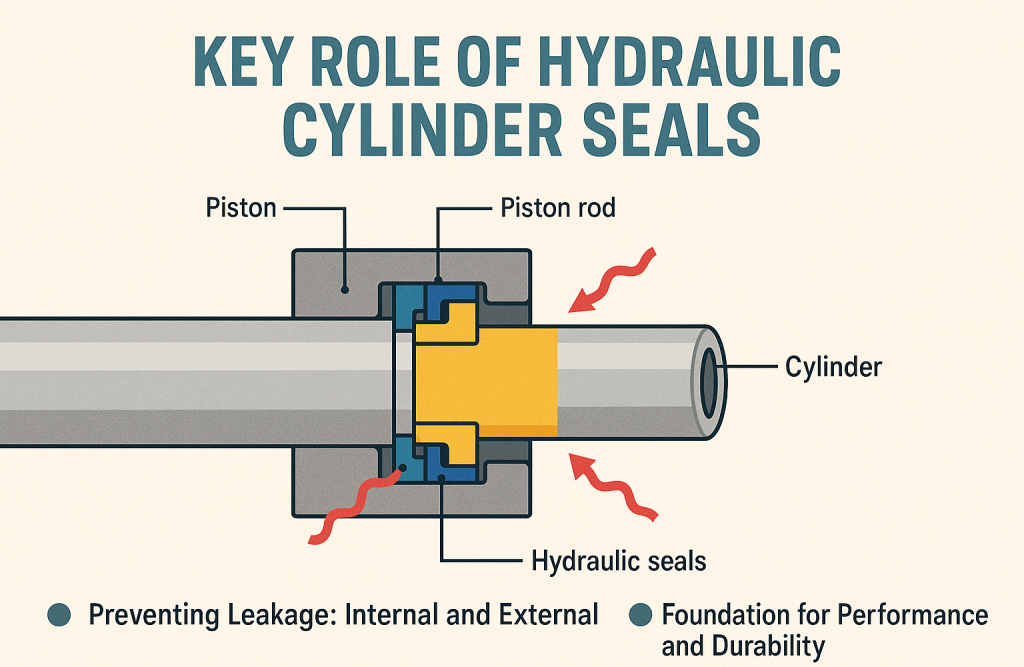

Key Role of Hydraulic Cylinder Seal

Preventing Leakage: Internal and External

Their primary responsibility is to precisely control the flow path of hydraulic fluid, preventing unwanted internal and external leakage within the cylinder.

- External Leaks: These not only result in wasted hydraulic fluid and environmental contamination but can also pose significant safety hazards.

- Internal Leaks: More insidious and often more damaging, internal leaks cause pressure imbalances across the piston, leading to cylinder “drift” or “creep”—for example, a crane arm slowly descending without operation, or a clamp failing to maintain adequate grip on a workpiece.

Protection of Internal Components

Furthermore, seals play a vital role in protecting the cylinder’s internal precision components by preventing external contaminants like dust and moisture from entering and eroding the piston rod and cylinder bore. This effectively reduces wear and extends the overall lifespan of the hydraulic system and the equipment itself.

Foundation for Performance and Durability

Therefore, selecting and maintaining the correct hydraulic cylinder seals is the cornerstone for ensuring durable, stable, and highly efficient operation of your machinery.

Types of Hydraulic Cylinder Seals

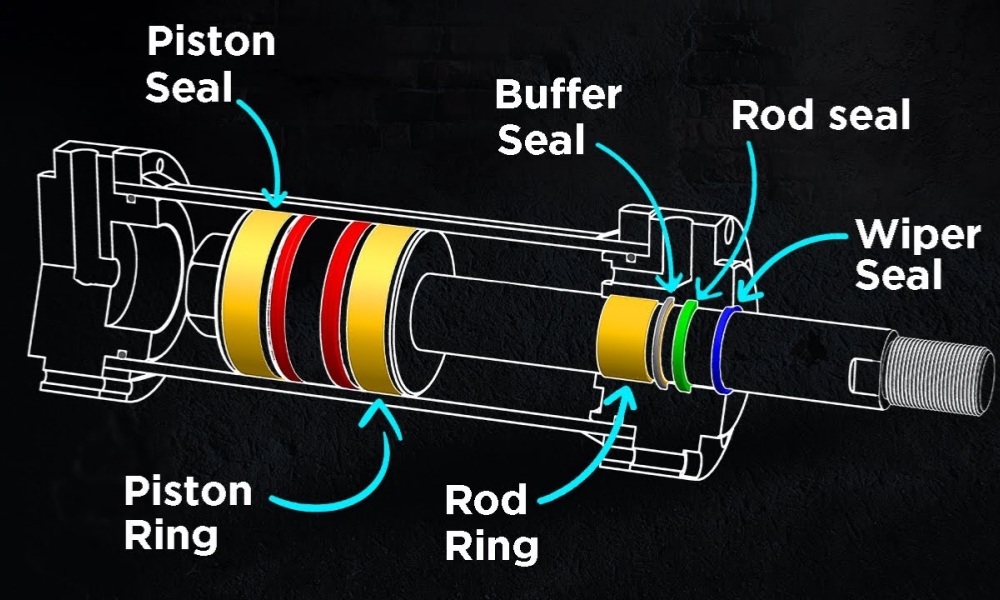

Core Dynamic Seals

The most common and core seals, designed for moving parts, include:

- Piston Seals: Mounted on the piston, these are responsible for preventing fluid crossover between the two sides of the piston (internal leakage), ensuring efficient force transmission. They come in various designs such as U-cups, V-rings, or compact seals, adapted to different pressure and friction demands.

- Rod Seals: Installed at the cylinder head, these are crucial for preventing hydraulic fluid from leaking externally past the extending piston rod. These seals must exhibit excellent wear resistance and pressure capabilities.

- Wiper Seals (Scrapers): Positioned on the outer side of the rod seal, their primary function is to scrape off dirt, dust, and moisture adhering to the piston rod during its extension and retraction, thereby protecting the rod seal and the internal system from contamination.

Support and Static Seals

Beyond the core dynamic seals, other vital components ensure overall sealing integrity:

- Wear Rings (Guide Rings): These support the piston and piston rod, preventing metal-to-metal contact that causes wear and potential damage to the seals from side loading.

- O-Rings: Serving as static seals, these are widely used in non-moving connections such as between the cylinder head and bore, or at port connections, to prevent static fluid leakage.

Importance of Material Selection

Selecting the appropriate hydraulic cylinder seal materials (e.g., polyurethane, NBR, Viton) is crucial and depends on specific factors like pressure, temperature, hydraulic fluid type, and the external environment.

Selection of the Right Hydraulic Cylinder Seal Kit

Finding the right hydraulic cylinder seal kit is a meticulous process that demands careful consideration.

Accurate Cylinder Identification & Dimensions

The first and most crucial step is to accurately identify your hydraulic cylinder model and dimensions.

This information, including bore diameter, rod diameter, and piston rod type, can typically be found on the cylinder’s nameplate, serial number, or by consulting the equipment’s original technical manuals.

These details are paramount to ensure that the hydraulic seal kit selection guide you follow leads to a kit that precisely matches your existing cylinder.

Secondly, you must thoroughly evaluate the actual hydraulic system pressure and operating temperature hydraulic seals will encounter.

Different pressure and temperature conditions necessitate sealing materials with varying strengths and temperature resistances. For instance, high-temperature or corrosive fluid environments may require specialized materials like Viton or or PTFE.

Ensure Fluid Compatibility

Simultaneously, it’s vital to confirm the compatibility of the hydraulic fluid being used with the chosen seal materials.

Incompatible fluids can cause seal swelling, shrinking, or degradation, leading to premature failure.

Maintenance & The Telling Signs of Hydraulic Cylinder Seal Failure

Hydraulic cylinder seals do not have an infinite lifespan; their failure is typically a result of multiple factors including prolonged wear, high-temperature degradation, hydraulic fluid contamination, improper installation, or overloaded operation.

Importance of Routine Preventive Maintenance

Routine preventive maintenance is of utmost importance.

This encompasses regular checks of hydraulic fluid cleanliness, timely fluid changes, inspection for piston rod surface damage, and adherence to manufacturer-recommended maintenance schedules.

Common Hydraulic Cylinder Seal Failure Symptoms

Even with diligent care, seals will eventually fail, emitting clear warning signs.

Conclusion

Finding and installing the right seals for your hydraulic cylinder is fundamental to ensuring its efficient, safe, and long-lasting operation. As discussed in this article, every step is crucial, from understanding the types and roles of seals to mastering precise selection strategies, recognizing failure signs, and performing timely maintenance. Investing in the correct hydraulic cylinder seal kit is not just a repair; it’s a wise investment in your equipment’s performance and operational efficiency. When faced with leaks, performance degradation, or other issues, remember that identifying and replacing the matching sealing solution is the key step to restoring your equipment’s robust power.