Construction machinery failures can cause costly downtime, delays, and unsafe conditions; without understanding hydraulic systems, problems could escalate. Here’s how to prevent disasters with the right knowledge.

Hydraulic systems are the backbone of construction machinery, converting fluid power into mechanical force for efficiency and reliability. Mastering how hydraulic systems work, their design, and maintenance needs is essential for optimal, safe operations.

Keep reading to uncover how these essential hydraulic systems really function and how they impact construction performance.

How Do Hydraulic Systems Work?

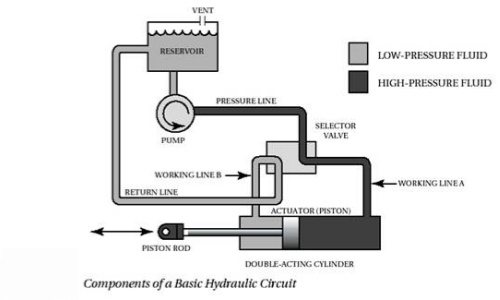

Hydraulic systems operate on a simple but powerful principle: transmitting force using an incompressible fluid, typically special hydraulic oil, within a closed circuit. When an operator sends a control signal—like moving a lever—a pump moves hydraulic fluid from a reservoir through pipes and hoses, directing it towards actuators such as cylinders or motors. As the pressurized fluid reaches the actuator, it pushes against surfaces inside (usually pistons), creating the required movement or force to perform tasks like lifting, pushing, or rotating.

This process allows massive weights to be lifted with precision, and complex movements to be controlled easily, making it ideal for construction hydraulics. The efficiency and force multiplication achieved by hydraulic systems lies in Pascal’s Law, which states that pressure applied to a confined fluid is transmitted equally in all directions. Proper construction hydraulic design maximizes this advantage to manage huge mechanical loads with reliability. Understanding how does a hydraulic system work is essential for troubleshooting and improving heavy machinery performance.

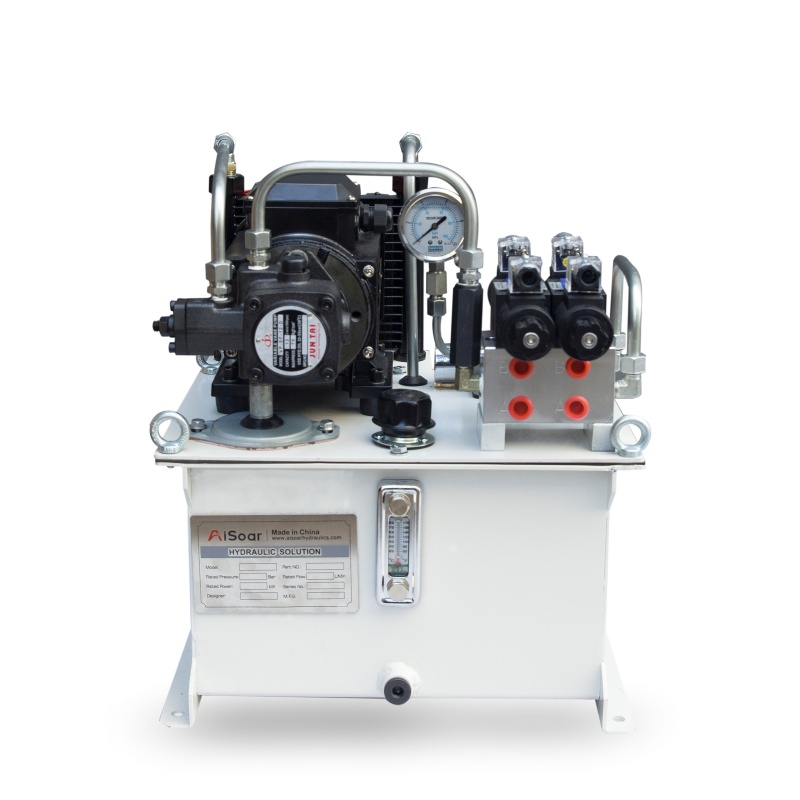

5 Basic Components of a Hydraulic System

Every hydraulic system, regardless of complexity, shares five critical components:

Reservoir: Stores the hydraulic fluid and helps to dissipate heat, remove air and allow contaminants to settle.

Pump: The ‘heart’ of the system, it moves the fluid from the reservoir and creates the flow needed for operation. Common pumps include gear, vane, and piston types.

Valves: Control the direction, pressure, and flow rate of the hydraulic fluid, ensuring precise movement and safety. Common examples are directional, pressure, and flow-control valves.

Actuators: These include hydraulic cylinders (which provide linear motion) and hydraulic motors (which provide rotary motion). They convert fluid power into mechanical motion.

Lines (Hoses & Pipes): Transport the hydraulic fluid throughout the system and connect the other main components.

A comprehensive grasp of these elements is key for anyone working with hydraulics systems, as issues in any one part can compromise machine performance or safety. Knowing the purpose and maintenance needs of these components is central to robust construction hydraulic design.

Common Causes of Hydraulic Systems Failures

Hydraulic system failures are a significant threat in the construction industry, often leading to costly repairs or dangerous accidents. The most common causes include:

Contamination: Dirt, water, or other particles entering the system can wear down pumps, block valves, and destroy seals.

Overheating: Insufficient cooling or improper fluid levels can cause hydraulic oil to break down, reducing lubrication and accelerating wear.

Leaks: Damaged hoses, seals, or fittings let fluid escape, causing pressure losses and environmental hazards.

Improper Maintenance: Skipping routine inspections or using incorrect fluids leads to early component degradation and unpredictable performance.

Incorrect Hydraulic Fluid Selection: Using the wrong fluid type undermines system efficiency and may result in catastrophic failure.

By understanding how do hydrolics work, operators and technicians can spot symptoms early and prevent most failures from escalating. Regular training and strict maintenance protocols reduce these risks considerably.

What Are the Main Maintenance Needs of a Hydraulic System?

Routine and preventive maintenance are vital for the reliable operation of hydraulic systems, particularly in harsh construction environments. Essential maintenance activities include:

Fluid Checks and Replacement: Regularly check fluid levels and quality; replace oil at recommended intervals, and use only approved hydraulic fluids to ensure optimal system longevity and operation.

Filter Replacement: Clean or swap out filters as scheduled to prevent contamination from entering sensitive components.

System Inspections: Frequently inspect hoses, pipes, and connections for leaks, cracks, and wear, addressing issues before they become critical.

Seal and Component Checks: Examine seals, valves, and cylinder surfaces for deterioration. Replace worn parts promptly to avoid leaks and pressure drops.

Temperature Monitoring: Ensure proper cooling, monitor for overheating, and maintain heat exchangers to prevent fluid breakdown.

Adhering to best practices in hydraulic system maintenance ensures maximum uptime and extends the service life of construction equipment. It’s also essential for sustainable and safe construction hydraulic design.

Why Water Is Not Used in Hydraulic Systems

Though water is abundant and inexpensive, it is rarely used as a hydraulic fluid in modern machinery. Principal reasons include:

Corrosion: Water promotes rapid rust and corrosion of metal components, leading to frequent breakdowns and shorter machinery lifespan.

Poor Lubrication: Water lacks the lubricating capability of dedicated hydraulic oils, resulting in increased friction, wear, and catastrophic failure of moving parts.

Freezing Issues: Water freezes at 0°C (32°F), while construction equipment often works in environments where subzero temperatures are common, risking total malfunction.

Low Boiling Point: Water vaporizes at relatively low temperatures, forming gas pockets that collapse upon compression (cavitation), damaging pumps and system parts.

Specialized hydraulic fluids are engineered not just for transmitting power, but also to lubricate, cool, and protect system components efficiently under wide-ranging environmental and operational stresses. For safe, long-lasting, and efficient machinery operation, selecting proper hydraulic fluid is a central factor in any practical construction hydraulic design.