Products

HYDRAULIC SYSTEM MANUFACTURER

Features & Details

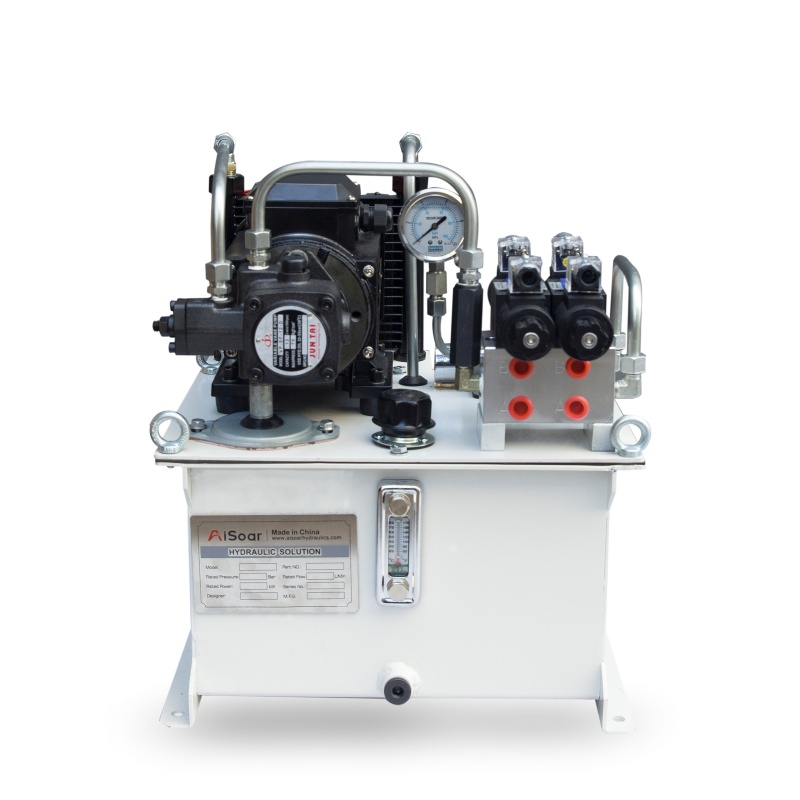

AiSoar Bar Manifolds: Unmatched Performance & Design Excellence

Our bar manifolds are meticulously engineered to deliver superior hydraulic system performance. Discover the features that set us apart:

Optimized Performance & Efficiency:

- Highest Flow, Lowest Pressure Drop: Designed for industry-leading flow rates and minimal pressure drop.

- Maximized Internal Flow: Internal galleries meet or exceed nominal port connections to ensure minimal pressure losses and optimal fluid velocities.

- Integrated Relief Options: Standard P to T Relief cavities (Sun and Common Cavity forms) are available, with ISO and other types as non-standard options.

Enhanced Installation & Serviceability:

- Generous Port Spacing: Maximized port spacing and edge distance for easier installation and simplified servicing.

- Dual-End Drain Ports: Common drain ports on both ends streamline installation and facilitate connecting multiple manifolds without extra fittings.

- Consistent Design Layout: Uniform design layout for every model, regardless of port code, ensures predictability.

- Flexible Port Isolations: “P” and “T” port isolations are available for manifolds up to 10 stations, with a second gauge port provided when “P” port isolation is present.

Versatile Configuration Options:

- Standard Flange Ports: Choose between UNC mounting threads with SAE Ports or Metric mounting threads with Metric Ports.

- Universal Mounting: UNC or Metric mounting bracket kits come standard with all bar manifolds.

- Simplified Assembly: Stud rods (ISO 03 to ISO 08) are available to simplify installation and reduce costs.

Product Specification

– Sizes 6 to 22

– Ductile iron, Steel 45, Aluminum

– Side or bottom ported

– SAE, NPT, and BSPP porting, flanged ports for larger sizes

– Includes mounting kit

– Other accessories available

Note: Bar manifolds may be purchased as complete assemblies upon request

Solution

For Tunnel Boring Machines (TBMs): AiSoar bar manifolds are integral to the intricate hydraulic systems within massive TBMs. Our diverse range of manifold sizes precisely manages critical functions like drill carriage, erector slide, and clamping mechanisms. Each control station, utilizing various modular valves, expertly governs the direction, speed, and force of individual movements, adapting to the demanding specifications of these impressive machines.

For Test Stands: Our bar manifolds provide precise control for demanding test environments, such as simulating airplane landing gear stresses. A dedicated manifold station directs hydraulic actuators for forward thrust, while another independently manages lateral forces. Despite sharing a single pump, each station’s unique modular controls, integrated via sandwich bodies beneath directional valves, ensure precise, independent adjustments of speed and pressure to meet stringent testing protocols.

NO. AS-1001

HYDRAULIC MANIFOLD BLOCK

AiSoar bar manifolds redefine hydraulic system efficiency. Designed to seamlessly integrate numerous hydraulic manifold valves, our units maximize performance while minimizing plumbing and potential leak points. Each hydraulic valve manifold block centralizes directional control valves, improving appearance and simplifying maintenance. Our enhanced designs, featuring options for X & Y ports with threaded or flanged connections, ensure your hydraulic valve manifold provides superior fluid direction and unparalleled system reliability. Experience streamlined installation and robust control.

Get a Quote